How does the FI pillar work?

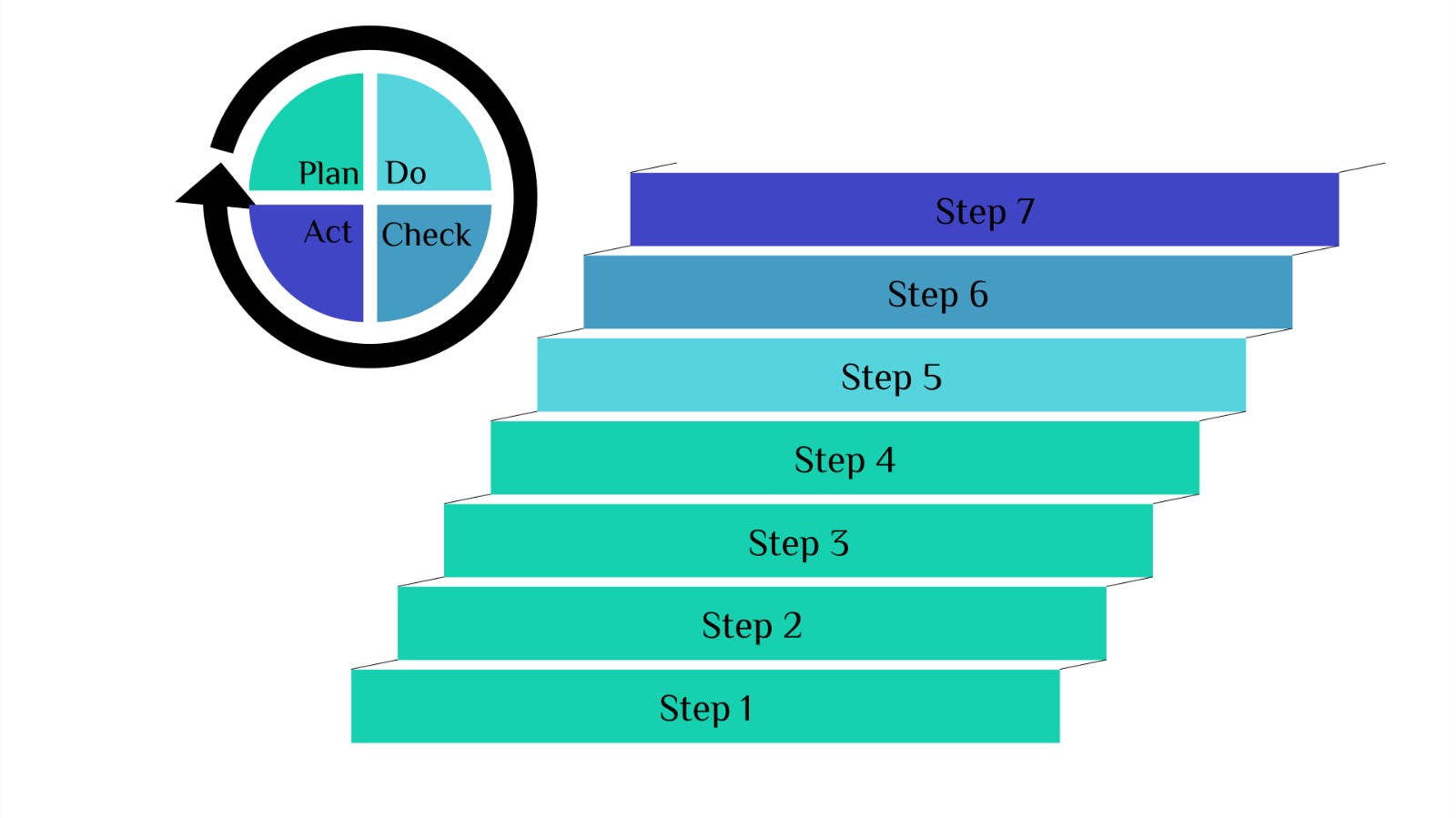

The main focus of the FI Pillar is continuous development, and it maintains this development process with the help of Kaizen projects. It concentrates on creating and implementing small improvement projects to ensure the constant development of the targeted staff members.

To implement the FI methods in your company, the first step is to define the scope of work. We can use the data that comes from C and D matrices in the CD Pillar. After the title is determined, the cause of this problem should be identified. Instead of traditional problem-solving tools, WCM primarily uses these methods:

- 4M Analysis: Same as 5M Ishikawa, more specific for the application on machines and examines the "Management" axis, which suggests the traditional 5M in its Column.

- Processing Point Analysis: The problem-solving methodology, unique to WCM, aims to solve the most complex problems.

- 5G: Regarding the problem-solving mindset, 5Gs are Gemba, Genbutsu, Gemjitsu, Genri, and Gensoku.

We identified the limits of the problems to be improved

and the reasons for them.

In the third step, we will set up the project to carry

out the improvement actions. Following the identified

cause, we know the applications we will deploy to

eliminate the problem, or we have about these good

practices. Therefore, depending on the application, we

can define a realization chart that we harmonize with

the data of the E matrix in the CD Pillar

In the fourth step, now that it is determined when we

should start the project, and when we should finish it,

we will set up the project by selecting the required

project team. We will act in line with the same

principles as Lean 6 Sigma projects. In the fifth step, we will continue the planning and the

actions to be implemented (Making the PDCA). We will

rely on a PDCA file to keep track of them and make sure

they are performed on time.

We can then use all possible tools to fix the problems:

- Design of experiments

- Seven quality tools

- Kepner Tregoe

- DMAIC

In the sixth step, we will make sure that the actions are effective and the problem is eliminated, in the same way as the PDCA Check step. In the WCM philosophy, we will focus on accurately measuring project benefits and costs. In the last step, actions performed through Inspections will continue in the same way. Besides, it is aimed to place the other obtained data learned during the project in the best way.